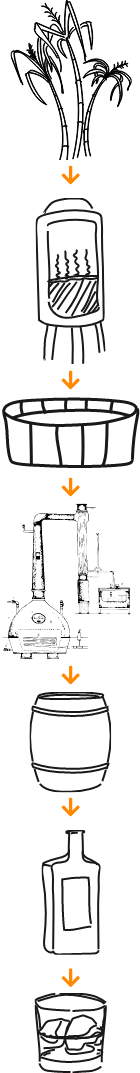

PROCESS

Sugarcane Harvesting

Evaporation

Fermentation

Distillation

Maturation

Bottling

Enjoy

Mauritius Rum: A Blend of History, Flavour, and Culture

Stage 1

Rum production in Mauritius has a rich history dating back to the early 18th century. During that time, the French took charge of sugarcane facilities left by the Dutch on the island. Although the production process has evolved over the years, the essence of rum-making remains unchanged.

Stage 2

The sugarcane juice undergoes an intricate series of evaporation processes, resulting in the creation of a dense, golden-brown liquid known as sugarcane honey. This substance is then further evaporated to produce the famous sugarcane molasses—a dark, viscous syrup of renown.

Stage 3

The sugarcane molasses is fermented with yeast to convert the sugar content into alcohol and carbon dioxide, creating a liquid called “mash.”

Stage 4

The mash is pumped into a pot still for distillation, a unique process that shapes the final product. Steam is used to vaporize volatiles, and if needed, the spirit undergoes re-distillation in a series of pots.

Stage 5

Next, the distillate is transferred to carefully chosen wooden barrels, usually oak, for ageing, acquiring its flavour and colour depth.

Stage 6

Following the ageing process, the spirits are blended to achieve the desired taste profile, and once blended, the iconic island rum is bottled.

Stage 7

The next step is the most important one: your enjoyment. Gather some great company, select your preferred House of Lords spirit, and make lasting memories around savor-worthy blends.

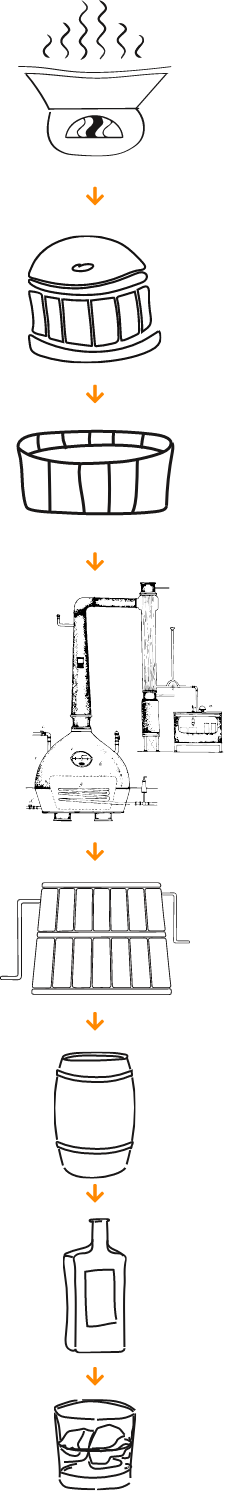

WHISKY PROCESS

Malting

Mashing

Fermentation

Distillation

Spirit Safe

Maturation

Bottling

Enjoy

Malt Whisky: A Liquid Meant for Celebration and a Subtle Aroma of Its Kind

Stage 1

Barley is soaked and spread out to germinate, activating enzymes that convert starch into sugar. Once germinated, barley, now called green malt, is dried in the kiln, and sometimes peat is added for a smoky flavour.

Stage 2

The dried malt is ground into a coarse grist, which is then mixed with hot water in stages. The water temperature gradually increases from around 67°C to nearly boiling. This sweet, sugary liquid is called wort.

Stage 3

The cooled wort is transferred to washbacks, where yeast is added, initiating fermentation. The yeast consumes sugars, yielding alcohol and congeners for flavour. After roughly 2 days, the result is a wash with 6-8% alcohol by volume, a crucial step in whisky production.

Stage 4

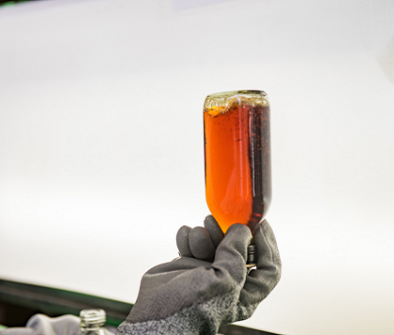

The wash undergoes a two-step distillation process. In the washstill, the first distillation separates alcohol from water, yeast, and pot ale residue. They then undergo a second distillation in the distillation apparatus. During which the more volatile compounds are separated out and redistilled when mixed with the next batch. Only the pure center cut, or heart of the run, which is about 68% alcohol by volume, is collected in the spirit receiver.

Stage 5

All distillates pass through the spirit safe, historically controlled by Customs & Excise. The Stillman relies on experience to assess the distillates without direct contact.

Stage 6

The resulting colourless, high-proof spirit, reduced to 63% alcohol by volume, is then poured into oak casks for maturation.

Stage 7

Once the maturation process is done, the whisky is now ready for an elegant bottling, encapsulating all the nuanced flavors obtained during maturation.

Stage 8

The final and most important stage of the process is the moment when you can finally savor the results of our craftsmen's diligent efforts. Whether poured neat, on the rocks, or with a creative cocktail twist, cheers.

GIN PROCESS

Malting

Mashing

Fermentation

Distillation

Spirit Safe

Maturation

Bottling

Gin: A Historical Tale of Flavour Abundance

Gin originated as a medicinal liquor made by monks and alchemists across Europe, particularly in southern France, Flanders, and the Netherlands, to provide Aqua Vita (an archaic name for a concentrated aqueous solution of ethanol) from the distillates of grapes and grains. It then became an object of commerce in the spirits industry.

Gin emerged in England after the introduction of Jenever, a Dutch and Belgian liquor that was originally a medicine. Although this development had been taking place since the early 17th century, gin became widespread after William of Orange led the 1688 Glorious Revolution and subsequent import restrictions on French brandy. Gin today is produced in different ways from a wide range of herbal ingredients, giving rise to several distinct styles and brands. After juniper, gin tends to be flavoured with botanical, herbal, spice, floral, or fruit flavours or often a combination, for a truly aromatic experience in a bottle.

The essence of SAP's S3Q Gin revolves around sophistication and well-being.

Gin is an integral part of our white spirits portfolio; with its aura of sophistication and flavour, it's the perfect muse.

Explore our range of meticulously crafted gins: SAP's S3Q Premium Dry Gin SAP's S3Q Premium Spice Gin SAP's S3Q Premium Orange Gin Enjoy being a distinguished gin connoisseur. Savour our distinctive variants with friends and family—cheers!

BRANDY PROCESS

Grapes Harvesting & Crushing

Fermentation

Distillation

Ageing

Blending

Bottling

Enjoy

Brandy: A Savoir-Faire Passed Down from Generation to Generation

Stage 1

The process of making brandy begins with the harvesting of grapes, although other fruits like apples, pears, or cherries can also be used. The fruit is crushed to extract the juice, creating what is essentially fruit wine.

Stage 2

Yeast is introduced to the fruit juice to initiate fermentation. During this stage, yeast consumes the natural sugars in the juice, converting them into alcohol and carbon dioxide, lasting several days to a few weeks.

Stage 3

Once fermentation is complete, the liquid, now known as "wine," is heated in specialized stills, which can be pot stills or column stills. As the wine is heated, alcohol vaporizes and rises through the still. It is then condensed back into liquid form, separating alcohol from water and other compounds, resulting in a spirit with a higher alcohol content known as "wine distillate" or "eau-de-vie."

Stage 4

The eau-de-vie is transferred to oak barrels for ageing, which can last for several years, during which the brandy interacts with the wood. This interaction imparts flavour, colour, and complexity to the brandy.

Stage 5

Brandies are made by blending eau-de-vies of different ages and characteristics. Master blenders carefully select and mix various eau-de-vies to achieve a specific flavour profile and consistency in the final product.

Stage 6

After ageing and blending, the brandy is filtered and diluted to achieve the desired alcohol content.

Stage 7

Once bottling is done, the aromatic brandy is ready for your late-night soirees of celebration—a toast to the good life.